Internal Combustion Engine Design Study

My passion for the automotive industry and mechanical systems inspired me to undertake this personal project focused on the Internal Combustion Engine (ICE), the heart of performance vehicles. The ICE is one of the most complex yet elegant mechanical systems ever engineered, perfectly blending precision, motion, and power. Through this project, I set out to deepen my understanding of its design and operation by creating a detailed 3D CAD model, conducting stress and thermal analyses, and fabricating a working 3D-printed engine model.

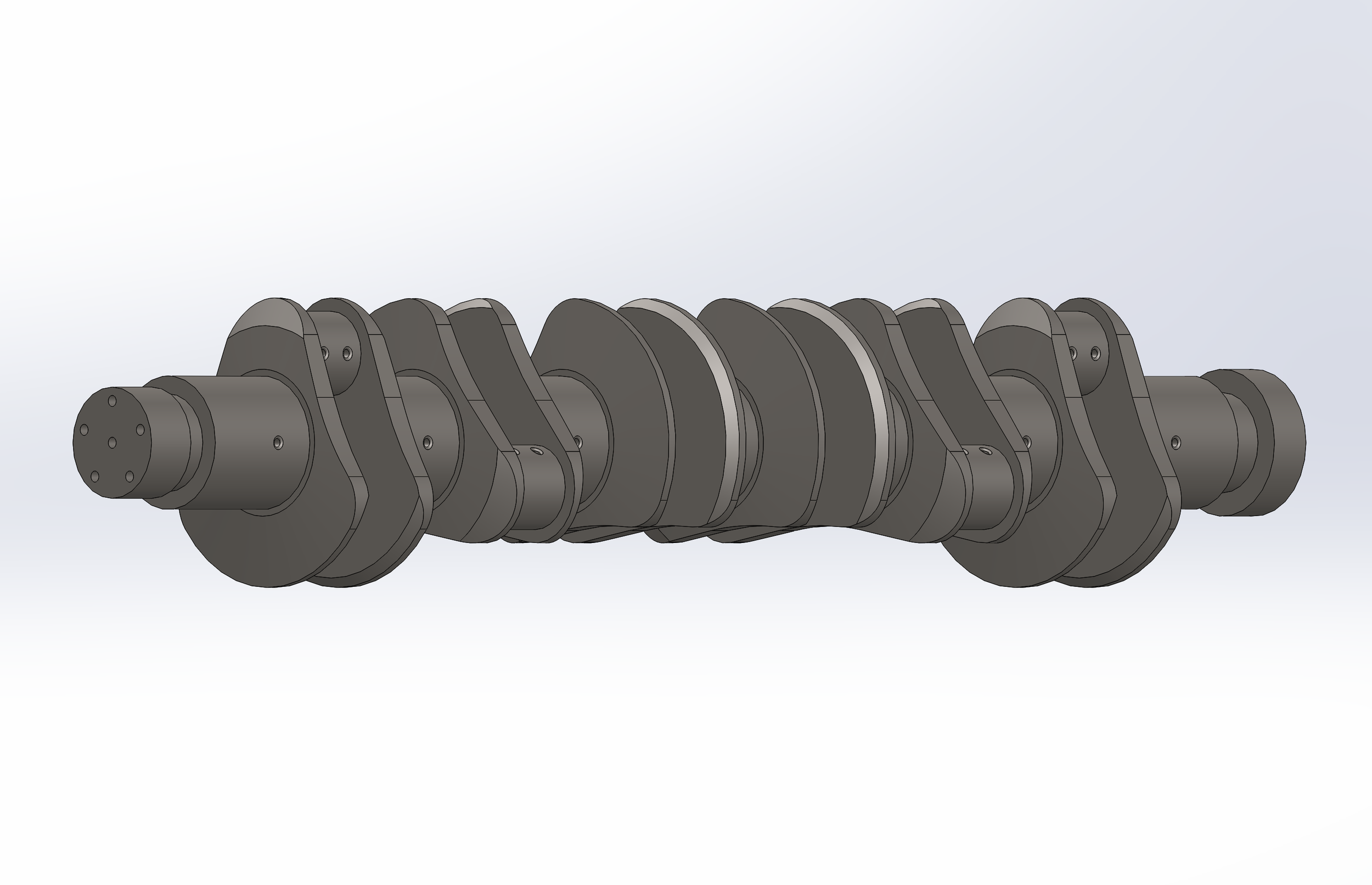

The engine model was fully designed in SOLIDWORKS, featuring a highly detailed supercharged 12-cylinder configuration. The goal of this stage was to capture the complexity and precision of an internal combustion engine while accurately representing all major mechanical assemblies. The model includes essential components such as the cylinder block, piston assemblies, crankshaft, camshaft, supercharger blower, spark plugs, and both intake and exhaust manifolds. Each part was carefully dimensioned and aligned to replicate realistic mechanical motion and assembly constraints. Special attention was given to ensuring accurate fit, internal clearances, and smooth interaction between moving components, creating a lifelike representation of one of the most sophisticated systems in automotive engineering.

CAD Design and Modelling

Complete Engine Assembly

Cylinder Block Assembly

Supercharger Assembly

Cylinder Head Assembly

Piston Assembly

Spark Plug

Intake Manifold

Crankshaft

Finite Element Analysis (FEA)

To evaluate the performance and durability of critical engine components, Finite Element Analysis (FEA) was conducted on the piston using ANSYS Structural and ANSYS Transient Thermal. The piston was selected due to its exposure to extreme mechanical and thermal loads during engine operation. In the structural analysis, the piston was modeled as an aluminum alloy with an adaptive mesh, and a combustion pressure of 10 MPa was applied to the piston crown to evaluate total deformation and equivalent (Von Mises) stress. In parallel, a transient thermal analysis was performed using the same material and mesh conditions, with a time-varying temperature load (22 °C to 300 °C) applied to the piston head and convective heat transfer applied to the remaining surfaces. These analyses provide insight into stress concentrations, thermal gradients, and heat flow, helping inform material selection, reliability, and long-term engine performance under realistic operating conditions.

3D Printing and Prototyping

To bring my engine study to life, I 3D printed a detailed replica of the Porsche 917 Flat-12 engine, an icon of performance and precision engineering. Printed on a Bambu Lab A1 over more than 200 hours, the model captured intricate internal geometries and moving components with remarkable accuracy. This project allowed me to visualize the inner workings of an engine, refine my 3D printing skills, and appreciate how digital design translates into tangible engineering through rapid prototyping and functional testing.